sheet metal tolerances Sheet metal is a slightly less precise method of manufacturing that relies on the cutting, bending, and stretching of thin sheets of metal to produce . Sheet metal welding, including TIG, MIG, and Stick, joins individual parts into a single unit. All of its working methods, tips, and more.

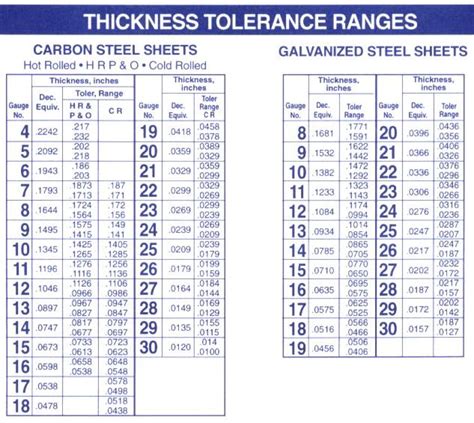

0 · steel thickness tolerance chart

1 · standard sheet metal tolerances chart

2 · sheet thickness tolerance chart

3 · sheet metal tolerances pdf

4 · sheet metal tolerances chart

5 · sheet metal thickness tolerance chart

6 · sheet metal gauge tolerance chart

7 · sheet metal dimensioning standards

Give your fabrics an instant shot of beautiful, washable, permanent color with Tulip ColorShot Instant Fabric Color. It’s perfect for a dash of color or for allover even coverage, and works .

Sheet metal is a slightly less precise method of manufacturing that relies on the cutting, bending, and stretching of thin sheets of metal to produce . Sheet metal tolerancing is a bit more complicated because of the fundamental differences in raw materials and manufacturing processes. Let’s . The first dimension, 11.20±0.25, has a tolerance equivalent to approximately ±.010 inches. This dimension alone is challenging – our standard tolerance sheet indicates that a dimension held across two bends can typically achieve ±0.015. The second dimension of .Sheet metal tolerances are the maximum permissible dimension deviation range during sheet metal processing. This concept is vital because it directly affects the quality and performance of the product. Ensuring that every product falls .

Specific tolerance guidelines integral to sheet metal fabrication are detailed in the table below. Each entry details the acceptable variance for various methods of fabrication and assembly.

Actual tolerances in sheet metal fabrication are influenced by various factors, underscoring the necessity of engaging with your fabricator at the initial stages of design. Ensuring CAD designs are aligned with Design for .

Mechanical Steel Sheet Mechanical Tolerances. Metals and Materials. . HR - Hot Rolled CR - COLD ROLLED Sheet Metal Gage (guage) size chart Carbon Steel Sheets. Gage. Thickness, Inches. Lbs/Ft 2. Decimal Equivalent. Tolerance Range. Weight. H .

1) All manufacturing tolerances used up to that point (such as laser-cutting tolerances, welding tolerances and more) 2) All bend tolerances for the entire part, added together We call this an uncontrolled dimensions because there .I'm having a minor debate with an engineer in work on flatness tolerances on sheet metal. We have been getting panels which aren't sufficiently flat (bowing in the centre by 1.5 mmm roughly). I suggested putting a flatness tolerance of 0.5. Is this flatness across a 250mm long 2 thick reasonable? I am able to find the tolerance of standard hot .

In sheet metal design, I would not be designing where I would require 15mil tolerance for anything to line up correctly. That's why god invented slotted holes. . I'm used to +/-.030" as the standard tolerance for bent sheet metal parts without really thinking about it. Tighter can be achieved, so +/-.015" seems reasonable if that's what you . This whitepaper helps describe a set of broad guidelines that you can use while specifying tolerances for your sheet metal parts drawing(s). Essentially, these are in place due to practical limitations of sheet metal forming, shearing and punching. Please note that these tolerances can change from manufacturer to manufacturer and this is .

This also means that tolerances in the title block of a drawing may be unnecessarily restrictive for certain dimensions and angles, while very appropriate for others. Critical Dimensions Sheet Metal Forming – Outside dimension should be used unless the inside dimension is critical.

Sheet metal tolerances describe the allowable variations in shape, size, and geometry for sheet metal fabrication. Metal tolerancing impacts project outcomes in multiple ways, including fit, functionality, manufacturing costs, and performance. Teams designing high-quality interchangeable parts require tight tolerances for better integration and .When International Standards that reference this standard permit sheet that is slit to less than 600 mm in width to be considered as sheet, tolerances shall be subject to agreement. a The thickness tolerances for sheet in coil form are the same as for sheet supplied in cut lengths but, in cases where welds are Industry Standards for Sheet Metal Tolerances. Different international guidelines standards are set for sheet metal tolerances. These guidelines and standards guarantee quality and consistency across different manufacturers and industries. ISO 2768. ISO 2768 is an important standard for general tolerances in sheet metal fabrication.

Tolerances: Sheet metal tolerances should not be tighter than necessary to make the part functional. Tight tolerances raise the cost of manufacturing significantly. Practical tolerances vary according to the design requirements. Tolerances of +/- .010 should be considered minimum. Linear tolerances should be held as loose as possible. These tolerance constraints apply not only when attaching two sheet metal parts together, but also when attaching sheet metal to other components such as weldments, or plastic/structural foam skins. Therefore when possible you should have any high tolerance alignment occur within one plane of sheet metal, strength can come from bends and . Sheet Metal Tolerances. Many engineers misunderstand sheet metal tolerancing—and for a good reason. Engineering curriculums are often skewed toward CNC machining and 3D printing, leaving engineers with a gap in understanding when it comes to sheet metal fabrication. Tight tolerances such as +/- 0.002" are the norm in machining. But with sheet .

Table of Contents. 1 How Powder Coating Adds Thickness to a Metal Fabricated Part. 1.1 Adjusting tolerances to account for powder coating buildup ; 2 Proactive Designs Pave the Way for Optimal Powder Coating Results; 3 Recommended Default Sheet Metal Tolerances; 4 Sheet Metal Powder Coating Tolerance FAQ. 4.0.1 How does powder coating affect the .General Tolerances ISO 2768-1 ISO 2768-1 is intended to simplify drawing indications and specifies general tolerances in 4 tolerance classes (f – fine, m – medium, c – coarse, v – very coarse). . CNC Machining, Vacuum Casting, Injection Molding, Sheet Metal Fabrication. Table 6 - General Tolerances on Symmetry Table 7 - General .Parts with the correct tolerances will still have excellent fit and function, with the added benefit of manufacturing efficiency. Hole Sizes Holes are produced by forcing a punch tool through the sheet metal in order to rip out a slug. When .Learn how to design for manufacturability with quick guidelines for sheet metal fabrication at Protolabs. menu. person. chevron_leftBack close. Services. Services. . Offsets are used to create Z-shaped profiles in sheet metal parts. .

Comprehensive resource of fabrication tolerances and dimensional variation guidelines for sheet metal manufacturing and fabrication. Transform your team's workflow with Protocase Designer Enterprise, the game-changing design . Our 'tolerances' are the maximum limits for dimensional variation that we can tolerate before a part is considered .Steel Sheet Thickness Tolerances.xls Author: MHumpal Created Date: 6/1/2021 9:00:24 AM .Sheet metal material stock has general tolerances for thickness. The following table is a quick reference for standard aluminum 5052 material thickness tolerances. Standard stock material tolerances may vary between alloys and treatments. Sheet metal with tighter tolerances sheet can be specified if required. Stock Material Thickness TolerancesFor example, the manufacturer recommends ISO 2768-mk for sheet metal parts and ISO 2768-fh for machined components. In the above example, “m” and “k” have defined the tolerance class. You can calculate the critical dimension tolerance using tolerance stack-up analysis. You can also use a tolerance stack-up calculator for this purpose.

“Having a handy guide to compare your called tolerances will profoundly affect your production,” Benson explained. By a “handy guide,” Benson means a guideline specifying reasonable tolerances for a formed part, both for linear and angular dimensions, as shown in Figure 1.. “You will no longer be making unreasonable demands, and no longer will you have . Sheet metal Tolerance Standrards, welding Tolerance Standards, General Tolerance Standards, IS 2102 Tolerance details, V groove pulley material Sheet Metal Tolerance Standards This blog discusses in over view of How to select sheet metal Tolerance as .

GENERAL TOLERANCES FOR FORM AND POSITION (DIN ISO 2768 T2) STRAIGHTNESS AND FLATNESS Ranges in nominal Tolerance class lengths in mm H K L up to 10 0.02 0.05 0.1 over 10 up to 30 0.05 0.1 0.2 over 30 up to 100 0.1 0.2 0.4 over 100 up to 300 0.2 0.4 0.8 over 300 up to 1000 0.3 0.6 1.2 over 1000 up to 3000 0.4 0.8 1.6

Sheet metal is manufactured and delivered from the processing mill rolled to the standard thickness that you specify, which is now metric. The sheet metal does however have a tolerance on the rolling thickness which needs to be taken into account when designing a tight fitting assembly, especially as the sheet metal material gets thicker. .The sheet metal parameters are dependent on the machines & tooling that will be used to bend the parts, which is far from universal between different manufacturers. 3D files - this is the closest to a “universal part” that you will find, as the machine software can unfold sheet metal parts using the specified sheet metal parameters. Typically, a customer will be satisfied with a certain range on a metal sheet. A tolerance of 48.000 +/- 0.125 inches by 96.000 +/- 0.125 inches is much quicker to produce and can be done at a lower cost. If the application can still be successful with a wider-ranging metal tolerance, then that is usually the best option. Types of Tolerances

electric box 2 level 24

Shop On-Q/Legrand On-Q 2-Gang Plastic New Work/Old Work Rectangular Electrical Box in the Electrical Boxes department at Lowe's.com. Provides recessed power and cabling connections for flat panel and TV installation.

sheet metal tolerances|sheet thickness tolerance chart